Compressed air leakage mapping

Why it is important to deal with compressed air leaks?

-

Ensuring the reliability of compressed air machines

-

Extending the life of pneumatic tools

-

Improving people’s working conditions

-

Compressor life extension

-

Removal of pressure drops

-

Energy cost savings

-

More environmentally friendly

Compressed air leakage mapping is the best way to reduce the cost of a compressed air system and extend its life. The mapping provides a complete overview of all leaks and highlights the most problematic areas of the system.

The mapping is performed with the most modern SDT ultrasonic devices. The equipment helps to detect even the smallest leaks from noisy production. As an importer of SDT ultrasonic measuring devices, we can guarantee the most accurate and professional leak mapping service in Estonia! See more about SDT devices.

At the end of the mapping, a report is submitted to the customer, on the basis of which it is possible for the repairer to easily carry out the work. The report contains information on each leak:

-

leakage size and cost €/year

-

image of a localized leak

-

definition of defective part

-

a description of the correction actions

-

an estimate of the cost of the repair

-

leakage cost m3/min and €

-

cost-effectiveness calculations

-

leak priority definition

In addition, a label is added to each leak to make it easy for the repairer to find the leak point.

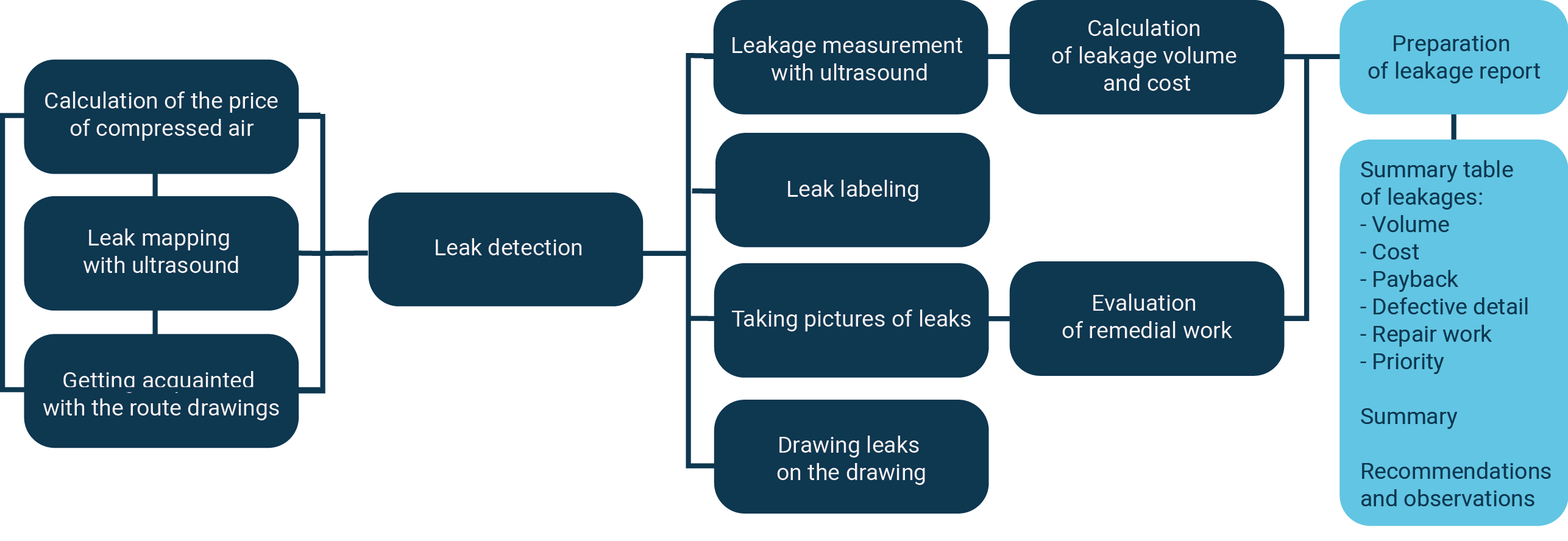

Stages of compiling an air leakage mapping

Mapping work can be ordered as a one-time service but also as a periodic service. As a periodic service, the system is inspected during predetermined time intervals. A report shall be prepared for each such mapping, which shall also indicate the quality of the previously performed repairs.

- Single mapping is ideal for controlling smaller (less than 50 kW) compressed air systems. Can also be carried out for larger if the leakage volume is small. The best way to detect the nature of system leaks.

- A mapping service designed for a system that requires constant maintenance and leaks is a common occurrence. Helps to periodically identify new leaks and assess the quality of previous repairs. The only solution to eliminate leaks completely.

Why choose compressed air leak mapping by DeltaE?

| DeltaE | Competitor | |

|---|---|---|

| 1. All leaks are found along the entire route | ||

| 2. All leaks are photographed | ||

| 3. The leak location is marked | ||

| 4. The volume of the leak is known | ||

| 5. Description of the defective part | ||

| 6. Detail repair cost | ||

| 7. Prioritize every leak | ||

| 8. Payback time with each leak | ||

| 9. Recommended actions to improve the well-being of the system |

Why can't you find leaks by listening with human ear?

Leaks are often removed in productions according to whether they are audible or not, and it is not taken into account that most leaks are not audible to the ear at all. This may be due to production noise or the geometry of the opening. Whether or not a leak of compressed air makes an audible sound depends on the geometry of the opening. The simplest example of this is blowing air with your mouth, when it is barely audible to blow with the same air, but when you put a whistle in front of your mouth, it blows the same sound very loudly. However, what does not depend on the geometry of the opening is the generation of turbulence. When air moves from a higher pressure vessel to a lower pressure environment, turbulence in the air occurs. Turbulence vortices always produce ultrasound that can only be heard with a device specifically designed to listen to ultrasound.

On average, one leak costs the company € 75 a year. In the event of one hundred such leaks, this means a loss of EUR 7,500 per year. 90% of all leaks in the compressed air system can be repaired. Repairing leaks will also help extend the life of your compressor as a result of longer compressor cycles (the compressor has a smaller load).