What is the main aim of the detailed inspection?

The main aim of the detailed inspection of heating, ventilation and cooling systems (HVAC systems) and building automation is to thoroughly map the existing situation, identify problems in detail and develop solutions.

The end result is a comprehensive need-based automation system, an initial design task and / or an already detailed renovation solution that can be implemented immediately.

Why a detailed inspection?

- HVAC systems of the building are overused and fail to work according to the needs.

- Lack of knowledge and competence to manage and upgrade systems.

- The indoor climate is not guaranteed – inadequate ventilation, too high indoor temperatures and low relative humidity.

- Energy consumption for utility systems is too high.

- Working in a building can be harmful or uncomfortable.

- Employee productivity is low and there are complaints about poor working conditions.

- HVAC systems and building automation need to be renovated and there is no detailed substantiated overview of the need and scope of construction.

- There is no remote administration, alarms, disturbances or monitoring of technical systems.

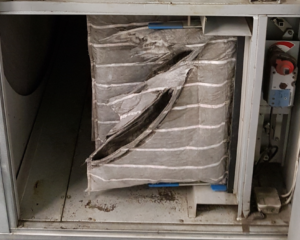

- The systems have been let down due to inadequate or insufficient maintenance.

Scope of work and activities to be performed

- Assessment and mapping of the current situation (central building automation, local automation, mapping and maintenance of HVAC systems)

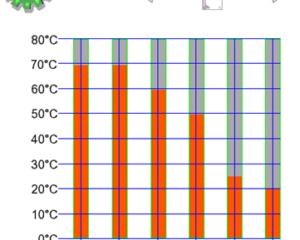

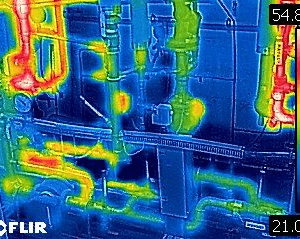

- Measurements (heat recovery efficiency, indoor climate measurements and thermography)

- Analyses (energy balance, consumption, indoor climate analyses and cost-benefit analyses)

- Energy simulations (modelling the existing situation, validating energy consumption as well as entering solutions and performing energy simulations)

- Solutions (preparation of design quotes, preparation of basic solutions for HVAC systems, development of climate and building automation solution, analysis of waste heat recovery opportunities, calculations, evaluation of comprehensive technical maintenance as well as measurement system volume and solution development

Inspection activities and schedule

- Collection of data and projects

- Inspections by experts

- Carrying out a survey

- On-site configuration of systems (if applicable)

- Analysis, development of solutions

- Preparation of the audit report

- Submission of final documentation and solutions

- Client training

- Implementing the next steps of the solutions

Construction of lighting installation

- Preparation of a work project

- Installing new cabling where necessary

- Installation of lighting and control equipment

- Lighting installation setting

- Monitoring

- Creating a visualization of a lighting installation

- Preparation of enforcement documentation

- Handover of solution to client and training

- Lighting design

What are the main problems and shortcomings that require further analysis?

| Problem | Impact/Solution |

|---|---|

|

Heat losses/ To insulate pipes correctly. |

|

Uneconomically high energy consumption / For a comprehensive overview, all space heating control solutions must be mapped in detail. During the mapping, the performance of the local automation must also be tested. |

|

Impossible to be verified on the basis of documentation / Due to the inspection and analysis it is possible to get an overview of the situation and performance of the systems and improve it according to the capabilities of the existing automation or supplement it with new automation. |

|

To get a thorough overview, a heat energy balance must be prepared. This presupposes the collection of additional consumption data. Additional data can only be collected through the construction of a measurement system. |

|

The efficiency of the equipment and the balance /disbalance of air exchange significantly affect the indoor climate and energy consumption. / To this end, it is necessary to further map the ventilation equipment serving the buildings, analyse their existing control automation (if any) and analyse in more detail the operation of the large ventilation equipment in the production building. In this scope, all technological exhaust fans, etc. must also be mapped. |

|

To get an overview of the utilization possibilities of residual heat, it is necessary to evaluate the production processes and the heat released in the process in different forms in more detail. |