Reactive energy and electrical quality

Reactive energy

Reactive energy is often used in production, industry and larger building complexes to the extent that it has to be paid for by the network operator. An additional cost can be eliminated with a high-quality reactive energy compensation solution.

We offer both implementation solutions and analysis of existing solutions, in case they do not fulfil their function. In the case of typical industrial plants, the payback periods of reactive energy compensation solutions range from 2 to 5 years.

Stages of developing a compensation solution

Stage |

Time |

| Determining the initial situation | week 1 |

| Data collection analysis (main consumption and, if necessary, additional measurements) |

week 2 |

| Solution development | week 2-3 |

| Solution presentation | week 4 |

| Implementation of a solution | week 5 |

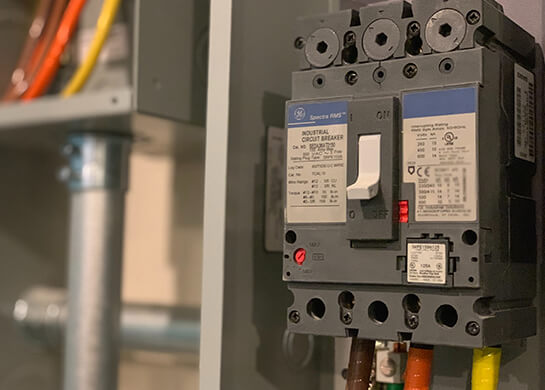

Electrical quality

In some cases, there may be problems in the electrical installation that seem to have no logical explanation. The reason is always there, but it needs to be clarified and an analysis is needed. It is important to compare the data with the standards as well as long-term experience to see the nature and core of more complex problems.

Typical electrical power quality problems.

- Switching off electrical equipment.

- Damage to electrical equipment.

- Abnormal restart of electrical equipment.

- Unexplained application of circuit breakers.

Stages of electrical quality analysis

Stage |

Time |

| Determining the initial situation | week 1 |

| Identification of potential concerns | week 2 |

| Measurements and data collection | week 2 – 3 |

| Data analysis and comparison of values with standards | week 4 |

| Solution development | week 6 |

| Solution presentation | week 7 |

| Implementation of a solution | week 8 |