Lighting installation design and construction

When designing a lighting installation in a building, we ensure compliance with the requirements of the lighting installation and maximum visual comfort for the user of the room. By ensuring good working conditions, we ensure the productivity and health of employees in the performance of their duties. Replacing traditional light sources one by one often results in overexposure or underexposure, high glare and an unoptimized solution. An unplanned solution is not cost effective.

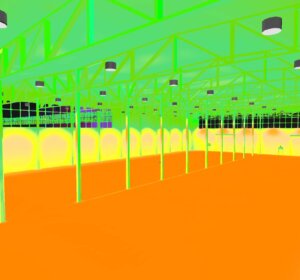

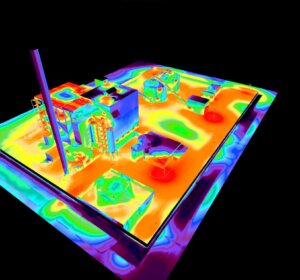

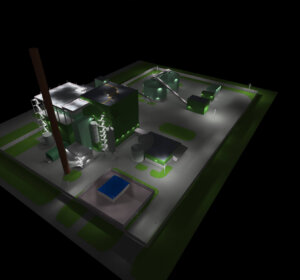

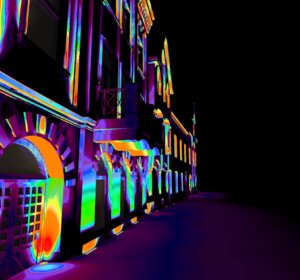

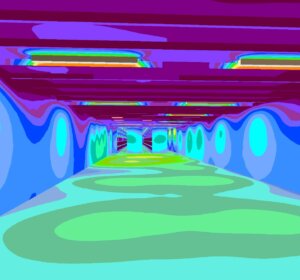

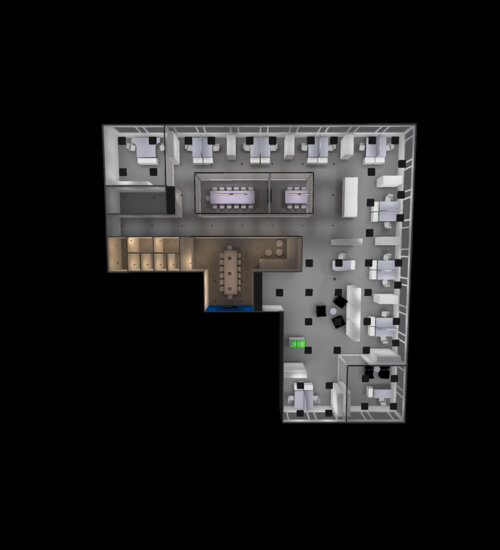

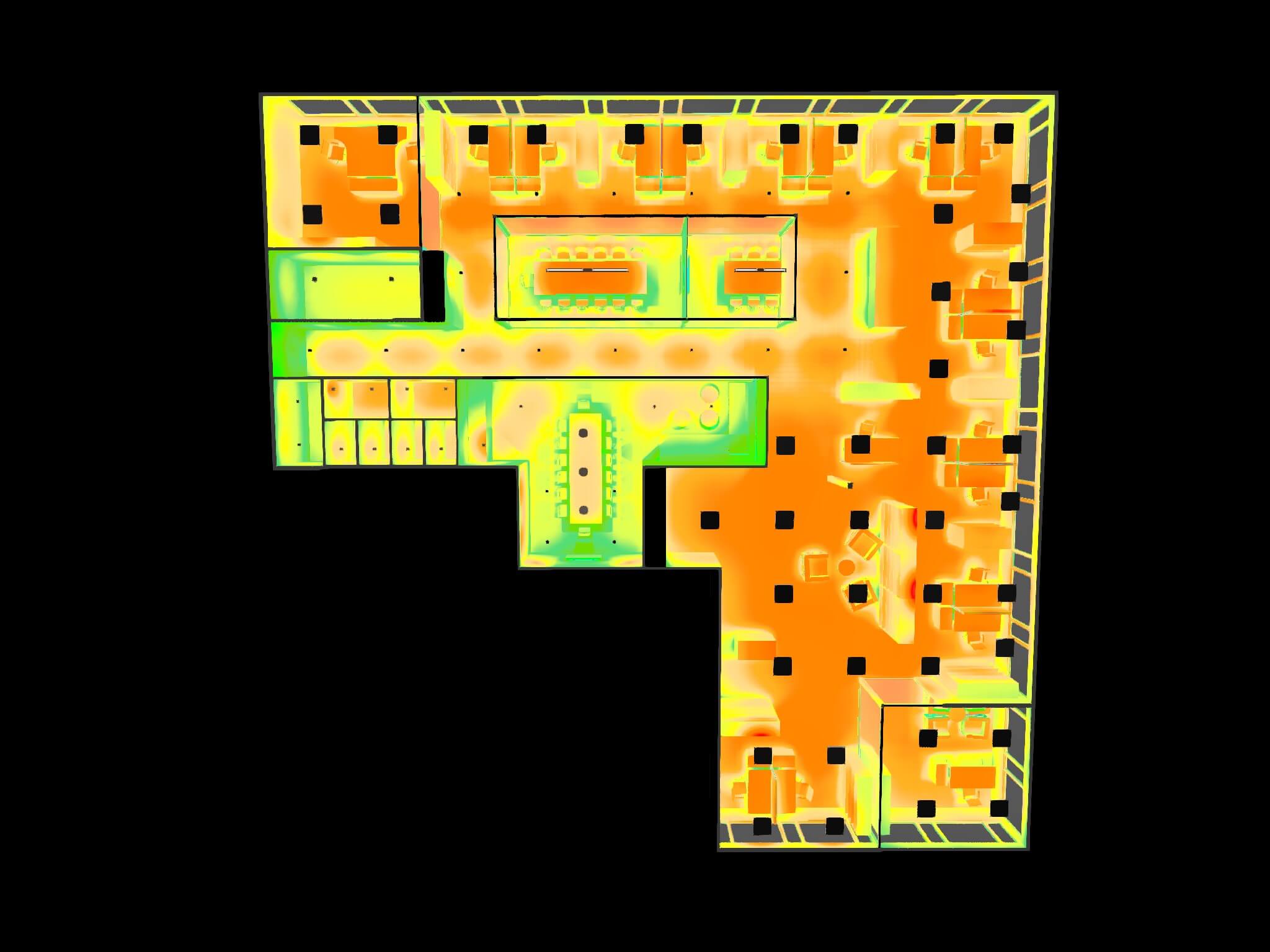

In order to achieve a proper and purposeful lighting solution, a lighting calculation is performed. In order to perform lighting calculations, the designed parts of the building are modeled with the necessary detail in a lighting calculation program. During the design, a cost-benefit calculation is performed, which results in the most optimal solution in terms of initial investment, profitability as well as energy and maintenance costs. The standards EVS-EN 12464-1: 2011 and EVS-EN 12464-2: 2014 set out the quantity and quality requirements for lighting solutions for most workplaces and related areas. In the event of non-standard lighting, the owner of the building must be held responsible in the event of an accident.

The design process always begins with an inspection of the lighting installation, during which the following becomes clear:

- Existing lighting installation current

- Customer concerns about the current lighting installation

- Customer expectations for a new lighting installation

- Possibilities to control lighting

- Current consumption of luminaires

- Employee satisfaction with the current lighting solution

- Room illuminance

- Uniformity of room illuminance

- Estimated brightness of room lighting

- Possibility to switch luminaires and switching groups

- Cabling condition

The lighting project describes:

- Precise project definition

- Problems with images of the current lighting installation

- Lighting requirements

- Description of new luminaires

- Emergency lighting and its necessity

- Maintenance factor

- Lighting maintenance

- Lighting control principles

- Lighting installation control parameters and achievable savings potential

- Lighting installation visualization options

- Measurement and monitoring of the lighting installation

- Basic principles of luminaire installation

- Similar work done in the past

On the basis of the project, it is possible to prepare a working project on the basis of which the lighting installation is ready to be built and provides important input on the need to implement control logics.

Parts of the project

- Delimitation of design work

- Lighting parameters

- Description of the existing lighting solution

- Lighting requirements

- Used luminaires

- Maintenance factor and installation maintenance

- Lighting control and automation

- Emergency lighting

- Installation and layout

- Lighting calculation

- Economic calculation

- Solution offer

Lighting installation construction

- Preparation of a work project

- If necessary, install new cabling

- Installation of lighting and control equipment

- Lighting installation setting

- Taking into monitoring

- Creating a visualization of a lighting installation

- Preparation of enforcement documentation

- Customer handover of solution and training

Lighting installation design process

Schedule of the design and construction process

| Design process | Time |

|---|---|

| Site inspection and information gathering | 1. week |

| Customer training and approval of conditions | 2. week |

| Design and models | 2. – 4. week |

| Economic calculations | 5. week |

| Project presentation | 5. week |

| Construction process | Time |

| Approval of the lighting solution | 1. week |

| Delivery of luminaires | 1.- 6. week |

| Preparation of a work project | 2. week |

| Construction | 7. – 10. week |

| Measurement of lighting parameters | After installation |

| Enforcement documentation | After installation |

What are the main design and construction errors?

| Problem | Impact |

|---|---|

| Under lighting | Premises that are too dark make it difficult to perform a task, the long-term effects of which are a deterioration in a person’s eyesight.lmanägemine halveneb. |

| Overexposure | Excessively light areas cause direct glare and cause the eyes to squint, causing strong tension in the eye muscles. May cause tension headaches and impaired vision. |

| Glare | Glare is a sensation caused by excessively bright areas. To avoid mistakes, fatigue and accidents, it is important that glare is limited. High glare levels are one of the most unanalyzed aspects of lighting design! |

| Uneven lighting | Uneven lighting creates a strong light-dark contrast between over-bright and over-dark areas, which forces the human eye to constantly adapt and causes strong tension in the eye muscles. May cause tension headaches and impaired vision. |

| Flicker | Perceived flicker can be very disturbing to people both in their free time and especially during work, inhibiting the productivity of their work and the health of the human eye. In photosensitive people, flicker of light can cause seizures in more extreme cases. The effects of flicker are often manifested by tension headaches and rapid eye fatigue. |

| Wrong choice of finishing materials | Choosing the wrong finishing materials can cause visual disturbances. For example, a white table top with a high-gloss finish reflects a lot of light and can cause glare if the luminaire’s illumination angle coincides with the luminaire’s position. The same effect can occur when exposed to sunlight from the window. |

| Water in the luminaire | If the ambient humidity or the possibility of moisture penetrating the luminaire has not been taken into account in the design process and the luminaire protection class has been selected incorrectly, rapid depreciation of the luminaire is expected. |

| Chemically aggressive environment | If the design process does not take into account chemicals that are volatile in the environment, then a reaction may occur between the chemical and the luminaire components, leading to breakage of the components and rapid depreciation of the luminaire. |

| Failure to calculate the maintenance factor | The maintenance factor shows us how much we need to dimension over the lighting in order to ensure the results prescribed in the initial design task at the end of the luminaire’s life. This is the most common mistake in the design of luminaires, as a result of which it may happen that the lighting parameters do not meet the agreed requirements after half a lifetime. |

| Use of ladder tubes | In order to perform accurate light calculations with LED tubes, it is necessary to install LED tubes in the luminaire used and re-measure the luminaire in order to obtain a correct lighting calculation file. If this is not done, it will not be possible to perform the correct light calculation with LED tubes. |

| Lack of attention to lighting control | A well-designed controllable lighting solution ensures up to 70% additional savings in electricity consumption. |

| No test period is applied | Without the application of the luminaires and their control test period, the lighting installation will remain in operation in the initial setting and will not meet the objectives set in the initial task, as a result of which energy will not be saved. The test period is intended to eliminate configuration errors and anomalies and to make the necessary adjustments. |

| Incorrect luminaire layout | Other technical systems are not taken into account in the design and the luminaires are hidden behind the ventilation pipes |

| Cabling errors | Electricians are not familiar with luminaire control protocols and their cabling, so they do not know how to cabinet luminaires properly. This can result in the luminaires not working or the luminaire control modules burning out. |